Press System

NAOMOTO NP SERIES offers perfect pressing with no skill.

The unique automatic press system eliminates the hand ironing from your production and

also it gives constant quality.

NP-110

This energy and space saving utility machine makes layout changes in the sewing process simple.Individual functions of pressing time,pre-steam,steam and vacuum result in high quality and consistent finishing.

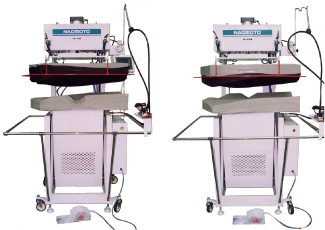

NP-151

Revolutionary ergonomic automatic system requires no hand iron for seam opening.Perfect results on difficult fabrics.

Tandem operation for maximum productivity.

*High quality and consistent finish.

*Higher productivity,easier operation.

NP-181

Revolutionary ergonomic automatic system requires no hand iron for seam opening.

Pressing time,pre-steaming,steaming and vacuum are programmed individually by computer.

*Cloth roll cover protects fabrics from damage.

*Machine is easy to move on casters.

*Fine distance adjustment between head and buck avoids impressions.

*Vertically acting head ensures even pressure.

*Simple turning device to turn pant legs after seam opening.

*Leg tensioning device assists seam opening and prevents seam folding.

Model |

NP-110 |

NP-151 |

NP-181 |

|

Voltage |

220V,1Ph,50/60Hz |

220V,1Ph,50/60Hz |

220V,1Ph,50/60Hz |

|

Electrical |

Boiler |

1.7kW (NP-110VB only) |

3.4kW (NP-151VB only) |

3.4kW (NP-181VB only) |

Head heater |

1.0kW |

(Steam heated) |

(Steam heated) |

|

Fan motor |

0.75kW |

0.75kW |

0.75kW |

|

Water feeding pump motor for boiler |

0.015kW |

0.06kW |

0.06kW |

|

Steam pressure |

(VB) 0.1MPa (1kgf/cm2) (V) 0.5MPa (5kgf/cm2) |

(VB) 0.3MPa (3kgf/cm2) (V) 0.5MPa (5kgf/cm2) |

(VB) 0.3MPa (3kgf/cm2) (V) 0.5MPa (5kgf/cm2) |

|

Steam consumption |

2.3kg/h |

4.6kg/h |

4.6kg/h |

|

Air pressure |

0.5MPa (5kgf/cm2) |

0.5MPa (5kgf/cm2) |

0.5MPa (5kgf/cm2) |

|

Air connection |

10mm dia. |

10mm dia. |

10mm dia. |

|

Machine dimension (Installation) |

(VB) W890xD855xH1600mm (V) W790xD855xH1600mm |

(VB) W1070xD972xH1670mm |

(VB) W1070xD972xH1670mm |

|

Steam connection |

1/2" |

1/2" |

1/2" |

|

Control |

Microprocessor |

Microprocessor |

Microprocessor |

|

*Remarks (VB)=with vacuum and boiler (V)=with vacuum, but without boiler

[ Single Legger-Pressing ]

Eliminating pressing mark, shining and wrinkles caused by steam.

NP-210L

*STRETCH FUNCTION

The adoption of STRETCHING to both upper and lower buck prevents any pressing mark.

*MICROPROCESSOR CONTROL

Pre-Input Program(Distance, Press, Upper Buck Steam, Lower Buck Steam, Vacuuming, Upper Buck Stretching, Lower Buck Stretching, Option Air)ensures the finest quality in finishing for your garments.

| Model |

NP-210L |

Voltage |

220V |

Working steam pressure |

0.5MPa (5kgf/cm2) |

Steam consumption |

20~30kg/h |

Working air pressure |

0.5MPa (5kgf/cm2) |

Air connection bore |

10mm dia. |

Back size |

(Upper) 460x1160mm (Lower) 460x1160mm |

Machine dimension |

W1800xD1400xH1700mm |

Steam connection bore |

1/2" |

Control |

Microprocessor |

[ Trouser Topper-Pressing ]

Eliminating pressing mark, shining and wrinkles caused by steam.

NP-400M

*CYCLE OPERATION

The adoption of STRETCHING to both upper and lower buck prevents any pressing mark.

*MICROPROCESSOR CONTROL

Pre-Input Program(Distance, Press, Upper Buck Steam, Lower Buck Steam, Vacuuming, Upper Buck Stretching, Lower Buck Stretching, Option Air)ensures the finest quality in finishing for your garments.

*Vartical pressing

*Waistband-clamp and stretching device

*Edge vacuuming

| Model |

NP-400M |

Voltage |

220V |

Working steam pressure |

0.5~0.7MPa (5~7kgf/cm2) |

Steam consumption |

20~30kg/h |

Working air pressure |

0.55MPa (5.5kgf/cm2) |

Piping connection bore |

(Steam inlet) 1/2" (Condensate outlet) 1/2" (Air connection) 10mm dia. (Exhaust air) 75mm dia. |

Machine dimension |

W1000xD1200xH1400mm |

Control |

Microprocessor |

[ Jacket Forepart Forming Press ]

NP-350R/L

*BUILT-IN VACUUM MOTOR

With Inverter control enables from various strength of vacuuming power during program.According to the material,vacuuming strength can be adjustable.

*MICROPROCESSOR CONTROL

Pre-Input Program( Press, Upper/Lower Buck Steam, Vacuuming) ensures the finest quality pressing for your garments.

*Vartical pressing

*Precise Front Setting Positioning

*Press Pressure Adjustment

*Marking Laser

*Safety Bay / Caster Wheel equipped

| Model |

NP-350R/L |

Voltage |

220V 1Ph |

Electric Capacity |

0.75kW x 2 |

Rated Current |

5.5A x 2 |

Working steam pressure |

0.3MPa (3kgf/cm2) |

Steam consumption |

20~30kg/h |

Working air pressure |

0.5MPa (5kgf/cm2) |

Piping connection bore |

(Steam inlet) 3/8" (Air connection) 10mm dia. |

Machine dimension |

W1245xD1200xH1400mm |

Control |

Microprocessor |

[ Lapel Pressing ]

The difference is the lapel finishing results!

NP-250L

EXCELLENT FINISHING RESULTS

DEPEND ON LAPEL FINISHING

(FEATURES)

*Press pressure adjustment

*Vertical pressing axis

*Steam heater pressing buck

(OPTIONAL)

*Built in inverter vacuum control

| Model |

NP-250L (NP-250L-V) |

| Voltage | 220V 1Ph |

| Electric Capacity | 100W (850W) |

| Dimension | W1160xD1320xH1650mm |

[ Collar Pressing ]

Excellent Jacket Top Collar Finishing.

NP-260L

EXCELLENT FINISHING RESULTS

DEPEND ON COLLAR FINISHING

(FEATURES)

*Press pressure adjustment

*Vertical pressing axis

*Steam heater pressing buck

(OPTIONAL)

*Built in inverter vacuum control

| Model |

NP-260L (NP-260L-V) |

| Voltage | 220V 1Ph |

| Electric Capacity | 100W (850W) |

| Dimension | W700xD900xH1700mm |

[ FLAP PRESSING ]

Remove curving and puffing.

High efficiency press system.

NP-80

High quality press system to slove problem of curving and puffing especially summer wear fabric.

*Upper iron heaterequipped

*Steam Generator equipped

*Vacuum equipped

*Stacker is standard equipment

| Model |

NP-80 |

| Description | NBC light Boiler equipped, inverter controlled vacuuming and blowing |

| Electric Capacity | (Steam Generator heater) 1.7kW |

| Machine Dimension | W830xD620xH1600mm |